What’s the difference between a bobsleigh and a car? Tyre treads. They’re the one thing keeping your car from sliding around on the tarmac and, if Cool Runnings has taught us anything, this can only be a good thing. But, for such an integral part of driving, most of us give our tyre treads little thought beyond our driving theory exams. So how do these groovy bits of rubber keep us on the roads?

Get to Grips With the Basics

The key to a good tyre is traction. It’s the grip of the tyre on the road and is caused by the friction between the rubber and asphalt. The rougher the two surfaces, the higher the friction and the better the traction. Rubber and asphalt have a high coefficient of friction, so a smooth rubber tyre could get you along a perfectly dry road without disaster. The problem, as those of us who have face-planted outside the Singaporean Ministry of Education in our rubber flip-flops understand, is when it rains. When the roads are wet, the tyres are sitting on a layer of water and the friction between rubber and water is low (face-plantingly low).

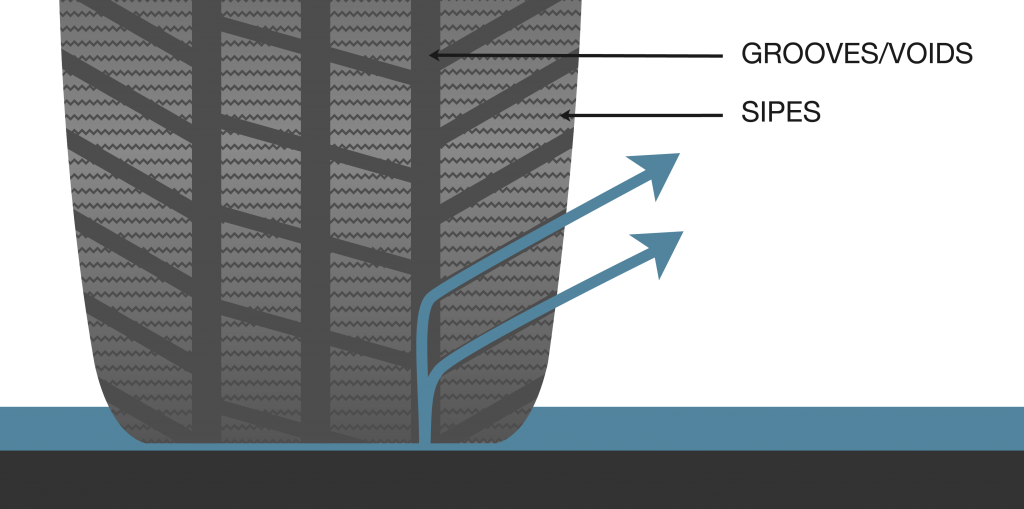

This is where tyre treads come in. The grooves (or “voids”) on tyres are there to provide a channel for the water. Allowing the water to escape from underneath the tyre keeps the rubber in contact with the asphalt, maintaining good traction and avoiding slippage. The same principle applies to driving in mud and snow: the grooves in the tread expel the snow or mud from under the tyre. Typically, the deeper the grooves, the better the traction in wet conditions.

Although the deep grooves remove most of the water, a very thin layer often remains. To solve this problem, treads have lots of smaller grooves called sipes. Sipes were patented in 1923 by John F. Sipe: the story goes that he was tired of slipping on the wet slaughterhouse floor, so he cut small grooves into the rubber soles of his shoes. In tyres, the tread flexes as it makes contact with the road, causing the sipes to expand and effectively suck up the water from the road.

So if all a good tyre needs is as many grooves and sipes as possible, why do we need symmetric, asymmetric, directional, all-season, winter and cold-weather tyres, and racing slicks? Unsurprisingly, there is a little more to tread design that just carving a few lines in some rubber.

Tyre Treads for Every Season

Tyre treads are a compromise between traction and rolling resistance. If you’ve ever had a flat or under-inflated tyre on your car or bike you will have experienced high rolling resistance: it slows you down and makes your engine (or legs) work much harder. A tyre made for snowy conditions has high traction but, using them in dry conditions, you would experience high rolling resistance and end up forking out much more on fuel to compensate. Cold-weather tyres are also made of a softer rubber (tyre rubber is a story for another time), allowing them to stay flexible in low temperatures, but the softer tyres are inefficient and wear down quickly in warmer weather.

Symmetric, asymmetric and directional describe the pattern of the tread. Directional tyres are the most easily recognisable, with V-shaped grooves making a chevron pattern. Also known as unidrectional, the tyres can only be fitted one way around, so are marked with the direction of rotation. You’ll find this design in winter and wet weather tyres, because the V-shapes are most effective at channelling water and snow away from the front of the tyre.

Symmetric tyres are your average Joe tyre: they’re cheaper than other types, you’ll find them as standard on most cars and they’re not specialised for a particular type of driving. The pattern is the same on both halves of the tyre (hence, symmetric) which means you can fit them either way round. If directional tyres are the mountain bike of the tyre world, symmetric tyres would be Boris Bikes: great for commuting but they won’t serve you well in tougher conditions. Symmetric tyres do, however, offer some advantages over other types of tyre, aside from price: they have good straight-line stability (due to the straight grooves running around the centre of the tread) and are low noise. Asymmetric tyres are a hybrid: the outside of the tyre has large, stiff tread blocks to help turning corners, whereas the inside of the tyre is more heavily grooved to shift water and improve stability in wet weather.

If, however, you’re designing a racing tyre, there’s only one thing on your mind: speed. Racing slicks, for dry tarmac racing, look like you forgot to put the tyre back over your inner tube. They’re smooth and made of a soft, sticky rubber; at high speeds the rubber melts, improving the traction. Luckily, the smell of burning rubber will not be coming to a road near you, because racing slicks are not legal for use outside the racetrack.

Tyre treads may not be the most glamorous part of your car, but they’re as carefully engineered as your touch screen key fob or augmented reality windscreen. Next time you’re heading out into the rain and singing the praises of window wipers, spare a thought for your tyre treads: there’s a lot more science going on under your feet than you might give them credit for.